Preparing For the Holiday Shopping Season

For most sellers, the holiday shopping season is the busiest, most critical time of the year.

On Amazon, things can get “crazy” for sellers, even if they have been through a holiday shopping season or two before on Amazon. In this chapter, we will discuss the steps you should be taking to prepare for the holiday shopping season on Amazon.

For many sellers new to Amazon, the magnitude of sales and potential customer inquiries in late November and December is hard to comprehend until you’ve been through it once yourself.

We also examine what daily tasks are needed to stay on top of your business through November, December and into January. We look at how to plan inventory levels so as to avoid selling out well before customers stop buying.

We also discuss how to ensure that your business doesn’t suffer unnecessary stock-outs immediately after December 25th.

Please note that if your product’s high seasonality is during a time other than November-December, the same issues apply, and the timing mentioned in this chapter should be adjusted to 1-2 months before that high season begins.

Not being prepared for the holiday season can lead to significant opportunity costs for your business. In the context of the holiday shopping season, these opportunity costs include revenue and profits that you didn’t generate because you ran out of inventory or had inventory mis-priced at a time that it could have sold at a higher or lower price.

Six Focus Areas to Prepare for the Amazon Holiday Season

There are five important areas that require your attention in the two- to three-month period leading up to the holiday rush:

1. Listings

While you still have time in September and October, check to make sure that the data on your listings are all in good shape. It’s also not a bad idea to check the data every week in November and December, just to make sure none of your listings have been artificially hurt by recently changed data that confuses customers or reduces the product’s search performance.

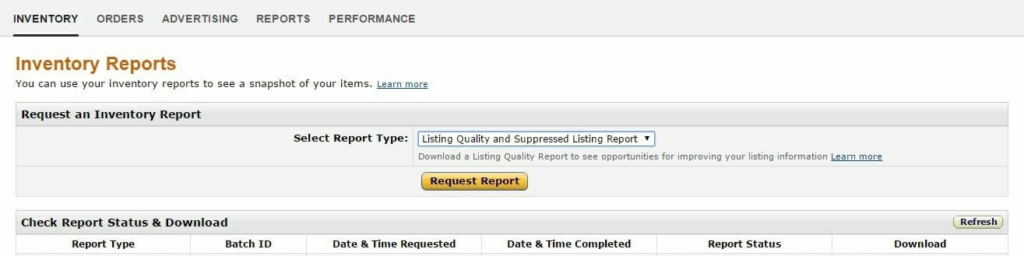

In Seller Central, go to Inventory -> Inventory Reports -> Listings Quality and Suppressed Listings Report.

You will see if there are any errors or data omissions on your feeds. Remember not all “errors” are a big deal, but you may find some that are suppressed because they have no product description or images. Those sorts of issues should be addressed, as they greatly help customers make a better decision about a product (and improve customer conversion).

If you want to see all of the fields on your listings, you can contact Seller Support and ask them to turn on the Category Listings Report for you. That report is available for only 7 days at a time in the Inventory Reports pull-down menu. Using this report, you can check all of your submitted data, and also see if any important categories of data are wrong or missing.

2. Inventory

Your ability to win the buy box is driven in part by your level of negative feedback along with your return rate.

Well before the holiday shopping season, you can make a data-driven decision as to whether to continue carry specific ASINs, or to hold back from selling them during the holiday season. The holidays are the busiest and most important time of the year, and you don’t want any item to result in your account being suspended or your buy box eligibility being hurt.

We suggest identifying any specific SKUs that account for a disproportionate share of either your negative feedback or returns. That way, you can determine if a small number of products are generating a disproportionate number of problems. To check on these dimensions:

Take your customer feedback data from the past six months, and organize it by ASIN to see which ones are generating a large quantity of negative feedback.

Similarly, look at your customer returns data in the Reports -> Fulfillment -> Customer Concessions -> Returns section to see which of your products have experienced extensive returns over the past six months.

3. Demand Modeling

While we are not aiming to provide a comprehensive statistical lesson on how to model future demand, here are a few issues to consider:

If you look at your monthly sales across the year, it’s quite likely that your November sales will be 1.5 to 2 times higher than January-to-October monthly sales, while your December sales will be 2 to 2.5 times higher than your January-to-October monthly sales.

And if you sell in the Toys category, that December number can increase to well over 5 times the January-to-October monthly numbers.

Many categories experience a mini-blip in sales in the two-week period immediately after December 25, as people buy themselves items that they didn’t get as gifts.

Let’s talk about stock-outs and excess inventory issues now:

Sellers model their inventory levels in all sorts of ways, but it’s important to have some sense of what inventory you currently have, as well as what you likely should have for the holiday shopping season.

We cover some rules of thumb in a moment, but looking at the actual inventory reports regularly is useful.

Maybe it’s time to send more inventory into FBA, or time to reorder inventory that you fulfill yourself—either way, you need to be looking at inventory levels at least every one to two days during the holiday shopping season.

If you’re in a position where you can afford to buy some extra inventory, keep in mind that there are lots of items you’ll likely sell in January and February too, so why not buy enough inventory to keep you going through end of February? If you sell through it faster than expected in December, you’re much more likely to have enough inventory on hand to avoid too many stock-outs right before December 25.

While you don’t have to send all of that extra inventory into FBA right away, you’ll at least have the inventory available to send to FBA should demand for your products in December be higher than expected.

If you are using FBA, go to Inventory -> Manage FBA Inventory, and Set Replenishment Alerts to be notified when falling below certain quantities in FBA.

This is a rarely used tool that can help save you a lot of time, scrolling through your whole FBA inventory.

Realistically, you should have most of your holiday supply ordered before mid-October, and either readied for your own warehouses by the third week of November or for FBA facilities by the end of the second week of November.

Keep in mind that FBA facilities can get very busy by mid-November, and it may take 5 to 7 days for your products to be received and ready for sale, so you want to be sure your items have been received and are sellable before Thanksgiving.

And with the ever-creeping Black Friday sales starting earlier and earlier in the week, it’s a good idea to be ready for increased demand at the start of the Thanksgiving holiday week.

You should also be aware that Amazon has had holiday periods in the past where the FBA facilities are full and cannot accept any more inventory. At that point, it becomes a first-come, first-served situation.

As a result, it’s better to get your products into an FBA facility a couple weeks earlier and pay for the extra storage time. If you can’t get the products into FBA, you’ll find yourself either having to fulfill orders yourself or simply not able to make that inventory available for sale if you’ve been completely reliant on FBA.

Have you ever measured the opportunity costs you’ve incurred from being out of stock the 7 to 10 days before Christmas? I’ve had many sellers declare to me that their holiday season was very strong and better than expected, yet when I ask them when they ran out of stock of most products, they tell me that by 7 to 10 days before Christmas, most of the items were sold out.

Most sellers are surprised when I tell them that they actually lost out on huge volumes of sales. They soon realize that they left a lot of money on the table by not buying enough to take them all the way through the holiday shopping season.

Through the December month, you must track all of your inventory daily to check for inventory levels, and sell-through rates.

Are there changes in demand that you should know about, either to do a quick re-buy or to consider clearing out slow-moving inventory that you don’t want to be left with after the end of the year?

Keep in mind that by mid-December, you’ve got an excellent window of opportunity to clear through old inventory by cutting the price just as customer demand for most anything is peaking.

One often overlooked aspect of the holiday season is what to do to be ready for January. Lots of sellers end up with stock-outs right before or after December 25, resulting in lost sales after Christmas, even though demand falls in early January.

Don’t forget to get yourself enough inventory to carry through at least mid-January, when most suppliers come up for air again after the holiday season.

Avoid poor planning, and aim to have product available in January, even if it’s not delivered to you until mid- or late December.

4. Fulfillment by Amazon (FBA)

Even if you are fulfilling most of your orders yourself, it’s worth considering sending some inventory of each fast-moving SKU to FBA in order to take advantage of the extra 2 to 3 days of guaranteed pre-December 25 shopping that Amazon offers FBA sellers.

Depending on how days of the week fall on a particular year, Amazon communicates to customers that FBA products purchased up to 2 to 3 days before December 25 will arrive in time for December 25.

If products are fulfilled by sellers, Amazon doesn’t allow the same messaging, so sellers of self-fulfilled products typically lose out substantially to FBA offers during the few days just before December 25, a time when significant purchasing is still being done.

When we get down to the last 3 to 5 days of shopping, customers basically buy only items that will get to them by December 25.

So make sure you have some strategy for using FBA during the holiday shopping season, even if it’s for only the few days before December 25.

Regardless of how much FBA you’ve used during the January-through-October period, consider putting some of your inventory for all key SKUs into FBA in November and December. That way, you can keep up with order fulfillment without having to hire temporary warehouse staff of your own.

Amazon has this capacity and staffing under better control than any sellers, so using FBA during November and December will help you avoid capacity headaches in your own warehouse.

5. Pricing

Since many shoppers are buying gifts for others and not themselves, you should consider pricing your unpopular inventory competitively to appeal to them.

As mentioned earlier, consider reducing your prices on slow-moving inventory after December 12 to 15 to clear it out so you aren’t left holding it after Christmas, when demand for both popular and unpopular items falls significantly.

Amazon has rules about price-gouging, and those rules kick into high gear during the holiday shopping season. If you price products more than 10 to 15 percent above the stated list price, Amazon likely won’t let you capitalize on your Featured Merchant status for those items, even if you are selling the item through FBA.

And sales conversion drops significantly for offers that aren’t showing up in the buy box (90%+ of all sales go to the buy box winner, and your product won’t ever show in up the buy box if never featured).

Charging more than list price during times of high demand really is a tradeoff between higher margins and lower visibility of your products. Depending on what competitors are doing on the same items, you will have to figure out which approach makes more sense for you.

6. Returns

There are two different types of product returns to highlight here:

As a small miscalculation in demand could cause you to be stuck with a lot of inventory after Christmas, it’s important to have discussions well in advance with suppliers to find out what they will accept as returns after Christmas.

If you have a generous return policy with your suppliers, it’s worth stocking up a little more for the holiday shopping season.

And if you don’t have a generous return policy (or any return policy), look at liquidating items that are moving more slowly than expected, starting by December 12 to 15, so you aren’t left with so much product that would take you many months to sell through during the non-holiday shopping season.

What plans do you have in place to handle the increased number of customer returns in January? With so many more orders in November and December, you should expect many more returns in January. You’ll need to be ready with staffing to process returns and a process to send returned products back to your supplier.

And because customers don’t always return products in new condition with original packaging, instructions, and warranty materials, you need to develop a process for reselling returned items that may have to be sold in used condition on Amazon or on some other channel.